- Home

- News

- New Precision Cutting Disc Technology Shifting the Industry Standard" becomes "Revolutionary Precision Cutting Disc Tech Changes Industry Norms

New Precision Cutting Disc Technology Shifting the Industry Standard" becomes "Revolutionary Precision Cutting Disc Tech Changes Industry Norms

By:Admin

Introduction:

{Company Name}, a renowned global manufacturing company specializing in innovative industrial tools, has announced the release of its latest innovative product, the cutting disc. With decades of experience and expertise in the industry, {Company Name} has consistently led the market in developing cutting-edge solutions to address the evolving needs of professionals across various sectors.

Innovative Features and Technology:

The new cutting disc by {Company Name} sets new industry standards by offering a comprehensive range of features and cutting-edge technology. Incorporating state-of-the-art materials and precision engineering, this cutting disc ensures exceptional performance, prolonged durability, and enhanced cutting efficiency.

One of the key innovations of this cutting disc lies in its unique composition. Made from a combination of high-quality abrasives and reinforced resin, this advanced disc delivers exceptional precision cutting without compromising on durability. Designed to resist heat and wear during demanding applications, the cutting disc guarantees long-lasting performance, making it an ideal tool for professionals in heavy industries such as automotive, construction, and manufacturing.

Unparalleled Precision:

{Company Name}'s cutting disc is specifically engineered to provide maximum precision, enabling professionals to achieve the most accurate cuts possible. The meticulous craftsmanship and rigorous quality control measures employed during the manufacturing process guarantee unparalleled consistency in thickness, diameter, and overall cut.

The advanced technology utilized in the production of the cutting disc ensures reduced vibration, thereby minimizing the risk of user fatigue and ensuring a safe and comfortable working environment. Users can rely on this cutting disc for smooth, straight, and clean cuts across a wide range of materials, including metal, stainless steel, aluminum, and more.

Optimized Efficiency and Productivity:

{Company Name}'s cutting disc is meticulously designed to optimize efficiency and productivity in the workplace. The disc's unique composition and superior manufacturing process result in reduced cutting time and improved overall performance. With this cutting disc, professionals can complete their tasks efficiently while achieving outstanding accuracy.

Additionally, this cutting disc offers remarkable versatility, adapting to a variety of cutting applications. Its compatibility with different tools, including angle grinders and power saws, further enhances its usability and makes it a preferable choice across various industries.

Commitment to Safety:

{Company Name} prioritizes the safety of its customers, and this commitment is evident in the design and manufacturing process of its cutting discs. Every disc undergoes rigorous quality control tests to ensure compliance with the highest safety standards. The cutting disc's advanced features and enhanced durability minimize the risk of accidents, providing users with a reliable and secure cutting solution.

Conclusion:

As {Company Name} launches its cutting disc into the market, professionals from various industries can look forward to experiencing a new standard of precision, efficiency, and durability. With its superior cutting performance, advanced technology, and commitment to safety, this cutting disc will undoubtedly become an indispensable tool in the toolbox of professionals around the world.

Company News & Blog

New Precision Cutting Disc Technology Shifting the Industry Standard" becomes "Revolutionary Precision Cutting Disc Tech Changes Industry Norms

Title: Industry Leader Launches Cutting-Edge Cutting Disc Solution for Enhanced Precision and Efficiency Introduction:{Company Name}, a renowned global manufacturing company specializing in innovative industrial tools, has announced the release of its latest innovative product, the cutting disc. With decades of experience and expertise in the industry, {Company Name} has consistently led the market in developing cutting-edge solutions to address the evolving needs of professionals across various sectors.Innovative Features and Technology:The new cutting disc by {Company Name} sets new industry standards by offering a comprehensive range of features and cutting-edge technology. Incorporating state-of-the-art materials and precision engineering, this cutting disc ensures exceptional performance, prolonged durability, and enhanced cutting efficiency.One of the key innovations of this cutting disc lies in its unique composition. Made from a combination of high-quality abrasives and reinforced resin, this advanced disc delivers exceptional precision cutting without compromising on durability. Designed to resist heat and wear during demanding applications, the cutting disc guarantees long-lasting performance, making it an ideal tool for professionals in heavy industries such as automotive, construction, and manufacturing.Unparalleled Precision:{Company Name}'s cutting disc is specifically engineered to provide maximum precision, enabling professionals to achieve the most accurate cuts possible. The meticulous craftsmanship and rigorous quality control measures employed during the manufacturing process guarantee unparalleled consistency in thickness, diameter, and overall cut.The advanced technology utilized in the production of the cutting disc ensures reduced vibration, thereby minimizing the risk of user fatigue and ensuring a safe and comfortable working environment. Users can rely on this cutting disc for smooth, straight, and clean cuts across a wide range of materials, including metal, stainless steel, aluminum, and more.Optimized Efficiency and Productivity:{Company Name}'s cutting disc is meticulously designed to optimize efficiency and productivity in the workplace. The disc's unique composition and superior manufacturing process result in reduced cutting time and improved overall performance. With this cutting disc, professionals can complete their tasks efficiently while achieving outstanding accuracy.Additionally, this cutting disc offers remarkable versatility, adapting to a variety of cutting applications. Its compatibility with different tools, including angle grinders and power saws, further enhances its usability and makes it a preferable choice across various industries.Commitment to Safety:{Company Name} prioritizes the safety of its customers, and this commitment is evident in the design and manufacturing process of its cutting discs. Every disc undergoes rigorous quality control tests to ensure compliance with the highest safety standards. The cutting disc's advanced features and enhanced durability minimize the risk of accidents, providing users with a reliable and secure cutting solution.Conclusion:As {Company Name} launches its cutting disc into the market, professionals from various industries can look forward to experiencing a new standard of precision, efficiency, and durability. With its superior cutting performance, advanced technology, and commitment to safety, this cutting disc will undoubtedly become an indispensable tool in the toolbox of professionals around the world.

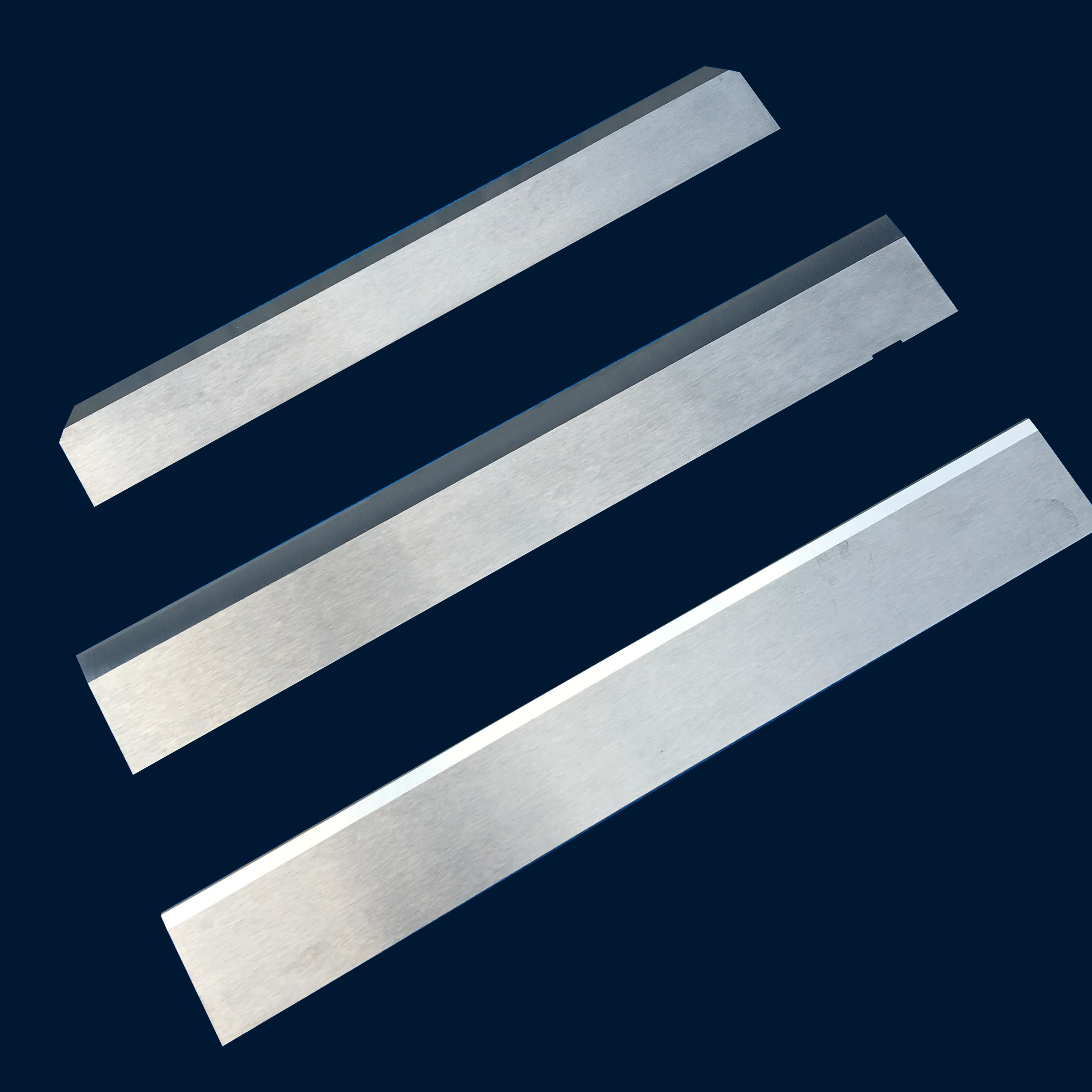

How to Replace Blades for Your Carpet Tool

Carpet Tool Replacement Blades Make Carpet Installation EasierInstalling carpets is a task that requires precision and the right tools. A carpet tool replacement blade is a crucial tool for professional carpet installers who want to deliver high-quality work without any hitches. Carpet tool replacement blades are designed to cut carpets quickly and efficiently, making the installation process faster and more enjoyable. The blades are made of high-quality materials that are durable and long-lasting, ensuring they stay sharp and ready to use.Carpet Tool Replacement Blades are made by a company that has been in business for over two decades. With years of experience in the carpeting industry, they understand the importance of having the right tools for any job. The company is dedicated to making high-quality tools that meet the needs of the carpeting industry. They carefully research and test their products to ensure they are up to standard and can withstand the rigors of daily use.One of the benefits of using Carpet Tool Replacement Blades is that they are versatile. They can be used to cut carpets of different thicknesses and textures. The blades come in different sizes and shapes to suit various carpet cutting needs. They are also easy to install, requiring minimal effort and time. Carpet installers can replace the blades themselves, which means they don't have to wait for a technician to come and replace them.Another advantage of Carpet Tool Replacement Blades is that they are cost-effective. The blades are sold at an affordable price, making them accessible to small and large carpeting businesses. The company also offers discounts to repeat customers, making it easy for businesses to purchase the blades in bulk, saving money in the process.Carpet Tool Replacement Blades are also safe to use. The blades are designed with safety in mind, ensuring that users do not injure themselves while using them. They are also meant to reduce downtime, as blade replacement can be done on site without having to halt operations.In conclusion, Carpet Tool Replacement Blades are a must-have for any professional carpet installer. They are durable, versatile, cost-effective, and safe, making them an excellent investment for any carpeting business. The company that produces the blades is dedicated to providing high-quality tools that meet the needs of the carpeting industry. With Carpet Tool Replacement Blades, carpet installation has never been easier.

Expertly crafted industrial cutting and grinding tools for the textile industry

In today's fast-paced world, the textile industry is growing at an unprecedented rate. With new materials being discovered and innovative machines being manufactured, the industry is continually evolving. However, one thing that remains constant is the need for high-quality cutting tools. Industrial textile cutting blades play a critical role in ensuring that the textile industry runs smoothly. In this blog post, we will discuss the importance of industrial textile cutting blades, their characteristics, and why you should choose Co-Max Machinery Tools for all your cutting tool needs.Importance of Industrial Textile Cutting BladesThe textile industry requires precision cutting, and that's where industrial textile cutting blades come into play. These blades are designed to effectively cut various materials, including cotton, nylon, polyester, etc. The blades must be sturdy enough to handle the dense and intricate materials used in the textile industry, as well as maintain their sharpness over time. Dull blades can not only harm the quality of the fabric but can also damage the machinery.Characteristics of Industrial Textile Cutting BladesThe challenges faced by the textile industry vary depending on the material being cut. As such, industrial textile blades need to have specific characteristics to deal with different textiles. For instance, blades used for cutting thin materials should be sharp, while those used for dense fibers should be sturdy enough to withstand the pressure. Other characteristics of industrial textile cutting blades include:Durability: The blade's longevity is essential for the textile industry. It is why blades should be corrosion-resistant and built to last.Precision: Precision is key when it comes to textile cutting. The blade should deliver precise cuts that do not undermine the fabric's integrity.Low maintenance: Blades that require little maintenance are ideal for the textile industry since they minimize downtime and increase productivity.Why Choose Co-Max Machinery Tools for Your Industrial Textile Cutting Blade Needs?Co-Max Machinery Tools is a professional company that is dedicated to producing high-quality industrial cutting tools. The company has over 20 years of experience in the industry and provides clients with customized cutting tools that cater to their specific requirements. Some of the reasons why you should choose Co-Max Machinery Tools for your industrial textile cutting blade needs include:Innovative technology: Co-Max Machinery Tools understands the demands of the textile industry and invests in innovative technology to provide clients with cutting-edge solutions.Durable cutting tools: Co-Max Machinery Tools provides clients with cutting tools that are durable and can withstand harsh working conditions.Precision cutting: Co-Max Machinery Tools ensures that their blades deliver precise cuts, minimizing the risk of damaging the fabric.Customized solutions: Co-Max Machinery Tools offers customized solutions that cater to clients' specific needs, ensuring that they get the best cutting tools that fit their specific requirements.ConclusionIn conclusion, industrial textile cutting blades play a significant role in the textile industry. They ensure that fabrics are cut with precision while maintaining quality and integrity. When it comes to choosing the right cutting tool, it's crucial to choose a company that provides durable, precise, and customized solutions. Co-Max Machinery Tools is a professional company that is dedicated to producing cutting-edge tools that cater to clients' specific needs. Trust us for all your industrial textile cutting blade needs and enjoy reliable and efficient services that cater to your requirements.

Top-Quality Double Edge Safety Razor Blades with Teflon and Chrome Platinum Coating

Bic Maggard Razors, a leading company in the shaving and grooming industry, has launched their latest product in the market - a line of double edge safety razor blades. Made with top-quality stainless steel, these blades are triple honed and coated with Teflon and chrome platinum. The product is made in Greece and promises to be a game-changer in the industry.The company takes pride in delivering superior quality products to its consumers. They ensure that their products are durable, well-designed and deliver excellent performance. With their newest addition, the company is keeping up with its reputation and is expected to set new standards in the market.The double edge safety razor blades are suitable for all skin types and are designed to provide a seamless shaving experience. The sharpness of the blades is well-balanced with the triple honing, providing a smooth cut with little to no irritation. The Teflon and chrome platinum coating makes the blades rust-resistant and adds to their longevity.It has been reported that the double edge safety razor blades by Bic Maggard Razors have been tested by a panel of experts, and the results have been favorable. The testers were impressed with the quality of the blades and how they performed. The blades have also been reviewed by regular users, who have reported the same outcome. The reviews pointed towards the longevity of the product and how well they shaved. Moreover, they mentioned the added benefit of cost-effectiveness, as the blades are said to last longer than other razors in the market.The company spokesperson was thrilled with the response from the audience. He stated, “We are excited about the launch of our double edge safety razor blades. We take pride in our products, and these blades are no exception. Our priority is to deliver superior quality products that are both cost-effective and efficient. And with these double edge safety razor blades, we are doing just that.”Bic Maggard Razors has been a trusted name in the shaving and grooming industry for many years. The company has come a long way, expanding its product line and innovating to bring the latest and the best in the market. The company is dedicated to delivering quality products that provide value to its customers.In recent years, there has been a shift towards using traditional shaving methods, and Bic Maggard Razors has been at the forefront of this trend. The company has been catering to the market demand by providing consumers with high-quality products that help them achieve the perfect shave.The double edge safety razor blades by Bic Maggard Razors are expected to take the industry by storm. The product is an excellent choice for individuals who prefer a classic shaving experience. Moreover, the blades are easy to replace, so consumers can switch them out as often as necessary, adding to their convenience.In conclusion, Bic Maggard Razors has done it again with their newest addition to the product line. The double edge safety razor blades are an excellent choice for anyone looking for a cost-effective way to achieve a smooth and comfortable shave. With their top-quality stainless steel, triple honing, and Teflon and chrome platinum coating, these blades are sure to impress. The company continues to set new industry standards with its innovative products, making them a go-to choice for anyone looking for quality in shaving and grooming products.

Top Supplier of Industrial Machine Knives, Blades, Sharpening, & Custom Blades

for optimal search engine optimization.Industrial knives are a crucial component of the manufacturing industry, used for cutting, shredding, and slicing various materials. From paper to plastic, the efficiency of the cutting process is highly dependent on the condition and quality of the industrial knives. To ensure the optimal functionality of these equipment pieces, it is imperative to find a reliable supplier of industrial knives.Hamilton Industrial Knife & Machine, a top supplier of industrial machine knives, blades, sharpening, and custom blades, offers a wide range of industrial knives that cater for diverse applications. The company has been in operation for years, giving them an edge in the industry by providing unmatched quality, professionalism, and competitive prices.Industrial knives supplied by Hamilton Industrial are of the highest quality, made from the best materials, and manufactured by skilled professionals. This guarantee ensures that customers receive high-performance equipment pieces capable of handling tough jobs without any glitches or failures. The company prides itself on providing premium and durable industrial knives that meet customers' requirements and budget.Hamilton Industrial's range of industrial knives includes straight knives, circular knives, and serrated knives. Straight knives work best in cutting soft materials like paper, leather, and textiles, while circular knives are used for cutting hard materials like metals, plastics, and composites. The serrated knives are ideal for cutting materials that are difficult to slice, such as frozen meat and baked goods.The company also offers custom industrial knives tailored to meet clients' specific needs. They use advanced technology and machinery to design and produce custom industrial knives that are precise, effective, and efficient. Hamilton Industrial's team of experienced professionals works closely with clients to ensure that they deliver industrial knives that match their exact specifications.Industrial knives from Hamilton Industrial come with exceptional sharpening capabilities, ensuring that customers can maintain their equipment pieces' optimal performance. The company uses cutting-edge sharpening machines that ensure precise, accurate, and reliable blade sharpening, which helps extend the operational life of the industrial knives.In conclusion, Hamilton Industrial Knife & Machine is a leading supplier of industrial knives that cater to a wide range of applications. The company provides high-quality, durable, and effective industrial knives that meet clients' specific needs. With state-of-the-art machinery and experienced professionals, customers are guaranteed premium products at competitive prices. If you are in need of industrial knives, Hamilton Industrial is the ultimate supplier to partner with for efficiency, effectiveness, and durability.

Reversible Screwdriver Blade for Maximum Durability - Phillips #2 + Slotted 6.0mm

for Precision Work, Wiha Phillips #2 Screwdriver Blade, Drive-Loc Handles, Collet Lock Handles, and Made in Germany.When it comes to working on delicate or intricate projects, having the right tools can make all the difference. That's why it's important to invest in high-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade.This blade is designed for use with both Drive-Loc and Collet Lock handles, giving you versatility in your toolkit. The blades are made from premium tool steel that has been through hardened and finished for maximum durability. This means you can rely on them to hold up to heavy use without losing their sharpness.One of the standout features of this blade is its double-ended design. With both a Phillips #2 screwdriver blade and a slotted 6.0mm (15/64") blade, you can easily switch between tasks without switching tools. This saves you time and effort, making it an ideal choice for professionals and DIY enthusiasts alike.As with all Wiha products, this blade is made in Germany to the highest standards of quality. You can trust that it will last you for years to come and give you excellent performance every time you use it.Whether you're working on precision electronics, appliances, or other household items, the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade is a must-have in your toolkit. Its high-quality slotted blades make it perfect for precision work, and its compatibility with Drive-Loc and Collet Lock handles make it a versatile choice for any project.Investing in the best tools means investing in top-quality blades like the Wiha 28110 Phillips #2 + Slotted 6.0mm Double-Ended Reversible Blade. Add it to your toolkit today and experience the difference a high-quality blade can make.

High Quality Slant Bar Safety Razor for Classic Shaving - Chrome Finish

Classic Shaving Offers Quality and High-End Shaving Products for the Modern ManFor years, men have always searched for the perfect shave, and many have found it in the Merkur "Hefty Classic" Safety Razor 37C - Slant Bar - Chrome. This razor is a product of Classic Shaving, which offers leading brand names and high-quality shaving supplies and accessories.Classic Shaving is dedicated to providing men with the best shaving experience possible. The company understands that the key to a great shave is not only a good razor but also high-quality shaving supplies like brushes, creams, and soaps. Classic Shaving provides a wide range of premium products that are designed to help men achieve the perfect shave every time.Merkur "Hefty Classic" Safety Razor 37C - Slant Bar - ChromeThe Merkur "Hefty Classic" Safety Razor 37C - Slant Bar - Chrome is one of the most popular products offered by Classic Shaving. This razor is a perfect combination of precision engineering, quality materials, and timeless design. The heavy-duty construction ensures that the razor will last for years, while the chrome finish gives it a sleek and sophisticated look.The razor is made by Merkur Solingen, a leading manufacturer of high-quality razors. The 37C has a unique slant bar design that provides a highly efficient and close shaving experience. The slanted blade allows for a more aggressive cut, which can be ideal for men with thicker beards or those who prefer a more efficient shave.The handle of the razor is designed to provide a comfortable grip, which makes it easy to maneuver during shaving. The razor comes with a safety feature that ensures that the blades are securely locked in place during use.Classic Shaving - More Than Just RazorsClassic Shaving offers more than just razors; the company provides a comprehensive range of grooming products for the modern man. This includes shaving brushes, shaving creams, soaps, trimmers, and grooming kits.Shaving Brushes - Classic Shaving offers authentic badger and boar bristle shaving brushes. These brushes are designed to exfoliate the skin and lift the hairs, ensuring a smooth and comfortable shave.Shaving Creams and Soaps - Classic Shaving offers a range of premium shaving creams and soaps made from high-quality ingredients. These products are designed to provide a luxurious lather that protects the skin while providing an excellent shave.Trimmers - Classic Shaving stocks a wide range of nose, ear, and beard trimmers. These trimmers are designed to provide precise grooming, making it easy for men to maintain their facial hair.Grooming Kits - Classic Shaving offers a range of grooming kits, which contain all the essential tools needed for proper grooming. These kits make it easy for men to maintain their appearance.ConclusionIn conclusion, Classic Shaving is a one-stop-shop for all of your grooming needs. The Merkur "Hefty Classic" Safety Razor 37C - Slant Bar - Chrome is just one of many high-quality products in Classic Shaving's range. Classic Shaving's commitment to quality, precision, and style ensures that you will always have a superior shaving experience. So why not invest in the best shaving products on the market and experience the perfect shave every time?

Custom Blades for Textile Cutting: Find the Perfect Fit for Your Application

In today's world, technology has influenced every aspect of our daily lives, including the textile industry. Custom machine knives for cutting textiles are essential for the creation of high-quality textiles quickly and accurately. York Saw is a renowned manufacturer of industrial blades that can be customized to fit specific textile cutting applications. Their expertise and capabilities make them an ideal partner for textile manufacturers looking to improve their operations.York Saw has been a leader in the blade industry for over 100 years. Their experience and knowledge of blade manufacturing has allowed them to create some of the most durable and reliable blades in the market. Their quality control measures ensure that their products perform to the highest standards for years to come.The importance of precise cutting in the textile industry cannot be overemphasized. When it comes to cutting fabric, accuracy and precision are crucial. In the past, manual cutting was the only option available. However, with technological advancements, the use of cutting machines has become the norm. These machines have revolutionized the textile industry by allowing for increased productivity, efficiency, and accuracy.The blades used in cutting machines play a vital role in determining the quality of fabric cut. The blade must be sharp and durable enough to cut through the fabric without causing any damage. If the blade is blunt or ineffective, it can cause significant issues, including jagged edges, uneven cuts and can even damage the fabric.York Saw provides high-quality industrial blades that are specifically designed for textile cutting applications. They offer a wide range of blades in different sizes, materials, thicknesses, and designs to meet the unique needs of each customer. The blades can be customized to suit the specific requirements of the textile manufacturer, including the material being cut, the thickness of the fabric, and the desired cutting speed. York Saw uses the latest technology to manufacture their blades, including automated machines that produce precise and accurate blades repeatedly. They also have an in-house team of experts that work with each customer to understand their unique needs and provide the appropriate solution. By working closely with their customers, they can develop a blade that meets their precise requirements and provides optimal performance, resulting in an increase in productivity and cost savings.In summary, York Saw is a leading manufacturer of industrial blades for textile cutting applications. Their commitment to quality, reliability, and precision has made them a trusted partner for textile manufacturers worldwide. They understand that every customer has unique needs, and they are dedicated to providing personalized solutions that meet their specific requirements. Their expertise and capabilities make them an ideal partner for anyone looking to improve their textile cutting operations. Contact York Saw today to learn more about how they can help with bespoke machine knives for cutting textiles.

High-Performance Slitter for Flexible and Rigid Materials up to 1300mm Width

If you're in the market for a high-quality slitter for your business, the (brand name removed) Razor Slitter could be the perfect choice. Designed for handling flexible materials like BOPP, PP, PE, PVC, and others without printing, as well as rigid and semi-rigid materials like card paper, cardboard, stamped paper, felt and all types of laminated, this slitter can handle a wide range of materials with ease.With a 1300mm roll entry that includes an aligner, air shaft, and electromagnetic control, the Razor Slitter is designed for maximum efficiency and precision. It also features a double articulated air shafts that includes individual electromagnetic control, and an electric photo cell to read lengthwise printing.Perhaps the most impressive feature of the Razor Slitter, however, is its razor cutting system. This specialized cutting system is designed to handle flexible materials with ease, ensuring clean, precise cuts every time. And with its special articulated support, the Razor Slitter can handle even the most challenging materials.Of course, the Razor Slitter isn't just designed for flexible materials. It also includes a rotating knife cutting system that can handle rigid and semi-rigid materials with ease. This makes it an incredibly versatile slitter, perfect for businesses that need to work with a wide range of materials.Other key features of the Razor Slitter include its easy-to-use digital programming panel, which allows you to quickly and easily program all operating functions and set up programmed memory functions. It also features a meter counter through electronic sensor and automatic stop sensor when programmed measurement is completed.Overall, if you are looking for a versatile and high-quality slitter that can handle a wide range of materials with ease, the (brand name removed) Razor Slitter is an excellent choice. So why wait? Request more information today and take your business to the next level!

How to Cut Holes in Cement Backer Board with a Jigsaw: A Homeowner's Guide to Cutting Hardie Backer Board. Blade Options for Cutting Cement Backer Board.

for Effective Backer Board Installation. When it comes to installing tile or other types of flooring in your home, proper preparation is essential for a successful outcome. One of the most important steps is installing the right backer board. Hardie board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. However, cutting Hardie backer board can be a challenge without the right tools and techniques. In this post, we will discuss how to cut holes in cement backer board with a jigsaw and the importance of choosing the right Hardie plank cutting blade.Cutting Holes in Cement Backer Board with a JigsawMany DIY enthusiasts and professional contractors alike prefer using a jigsaw for cutting holes in cement backer board. With its fine-toothed blade, a jigsaw can make precise cuts quickly and easily. To get started, you will need the following tools:- A jigsaw with a fine-toothed blade - A straight edge - Safety glasses - Dust mask - Gloves Here are the steps to follow:1. Place the cement backer board on a work surface, such as a sawhorse or workbench.2. Use a straight edge to mark the shape of the hole you want to cut 3. Put on your safety glasses, dust mask, and gloves 4. Insert the jigsaw blade into the hole you have drilled in the cement backer board 5. Turn on the jigsaw and follow the outline you have marked on the backer board 6. Apply firm and steady pressure as you cut through the cement backer board Choosing the Right Hardie Plank Cutting BladeTo achieve a clean cut on your cement backer board, you must use the right type of blade. A Hardie plank cutting blade is specially designed to cut through fiber cement products like Hardie board. Here are some factors to consider when choosing the right blade:- Tooth configuration: The blade should have a double-row configuration with extra-sharp teeth to prevent chipping and splintering - Diameter: The diameter of the blade must be suitable for the type of tool you are using - Material: Choose a blade made of high-quality carbide-tipped material, which is durable and long-lasting In summary, Hardie backer board is a popular choice for many homeowners because it is durable, moisture-resistant, and fire-retardant. Cutting holes in cement backer board with a jigsaw is a great option for those who prefer a fine-toothed blade. To achieve a clean cut, it is essential to choose the right Hardie plank cutting blade. With these tips in mind, you can install your Hardie backer board with ease and confidence.